X-Ray Assessments

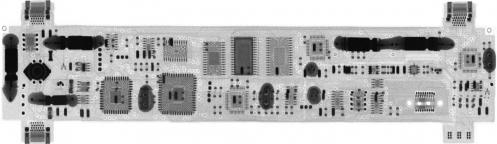

The use of X-Ray inspection within electronics manufacture has largely been associated with the Inspection of BGA's, LGA's, QFN's and CSP's. However, at CIL our Nordson DAGE QUADRA 5 & QUADRA 7 Pro Digital X-Ray systems also are used for many other things including CT Scan analysis. With many components using Thermal Pads and integrated heat-sinks, the importance of void free soldering and ensuring that these devices are correctly soldered is of utmost importance. High degrees of voiding means thermal predictions may be badly affected, and thereby affecting product reliability.

Components with hidden or BGA style joints are inspected using X-ray, as part of the in-process verification for NPI and Engineering assessments. Both the QUADRA 5 & QUADRA 7 Pro systems are very versatile and produces instant image capture and, if required, video footage of the assessment. The system is able to measure attributes and calculate aspects such as Void Percentages within a joint are; track & gap measurements; as well as the land and pad dimensions, including areas for calculating joint to pad ratios. We also use X-ray within our Anti-Counterfeiting Procedures as a non-destructive assessment of supplied goods. This is used to verify uniformity of supply and to view and investigate anomalies, please feel free to view our section relating to Anti-Counterfeiting procedures and practices.

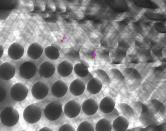

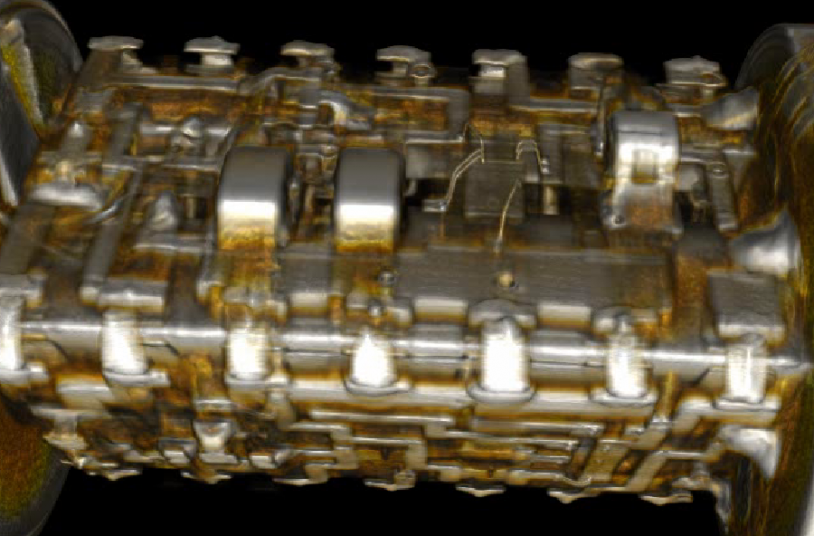

As well as conventional X-Ray inspection detailed above, the QUADRA 5 system is a "state of the art" platform and also has complete CT Scan capability. The Nordson Dage QUADRA 5 CT capability uses X-Plane to build X-Ray 3D images comprising up to 1000 distinct slices or image planes of the component being inspected. A slice will remove obstructions above and below the plane of focus so that only the regions of interest remain. Defects such as interfacial voids, cracks, HIP and other solder or manufacturing defects can be found and measured. This allows root cause investigation and corrective actions to be put in place.

The system produces ultra-high quality images using Nordson Dage's latest generation QuadraNT X-Ray source, which is 10 times brighter and intrinsically more stable than conventional X-Ray tubes. CT-Scan images are available on request

X-Ray Assessments are available as a stand-alone service, talk to our sales team for advice on a practical and cost effective course of action.

For more information on how Custom Interconnect can help you with solder jet printing, contact us today on sales@cil-uk.co.uk.